|

|

|

|

Pilt on illustreeriv

|

Kilbikarbik HVDRF 100Lx60K, A6/4, 2m/pc, hall Kood:

011701654

€ 14,20

/pc

(€ 17,61 /pc KM-ga)

Package 2m, unit price

7.1EUR/m

|

Saadavus:

Laos

|

Kaal:

0.985 kg/m

|

Maht:

0.0033 m3/m

|

Hulgipakendi kogus:

32m

|

|

|

|

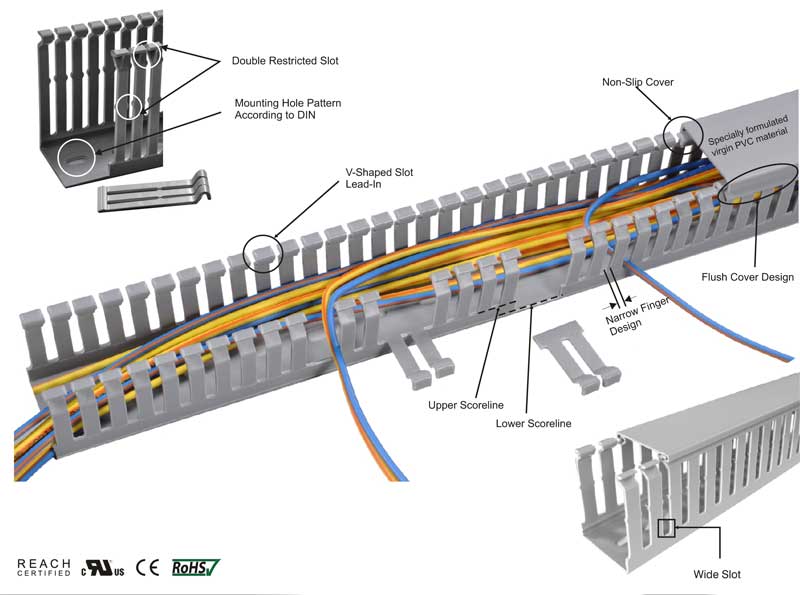

Wiring Duct HVDRF 100x60, slotted wall A6/4 and smooth lid, 2m, grey

|

Wire management solution.

The selection and design of Trinity Touch wiring ducts is to meet the maximum wire capacity needs and space constraint of the smallest wall

mounted panels to the largest integrated systems.

All the wiring ducts are manufactured from high impact, self extinguish, wrap proof rigid PVC with lead free material. PVC material carries

UL 94 flammability rating of V0 for excellent flame retardancy, continuous use temperature 50ºC (122ºF).

Wiring ducts includes solid and slotted styles, narrow slots/finger design provides more slot to closed fit the spacing of high density

terminal block and other hardware.

All the wiring ducts are available in different sizes. Premium-Duct comes in standard colour of grey in 1 meter and 2 meter lengths. Other

colours of wiring ducts are also available on request for minimum volume requirements.

|

|

|

|

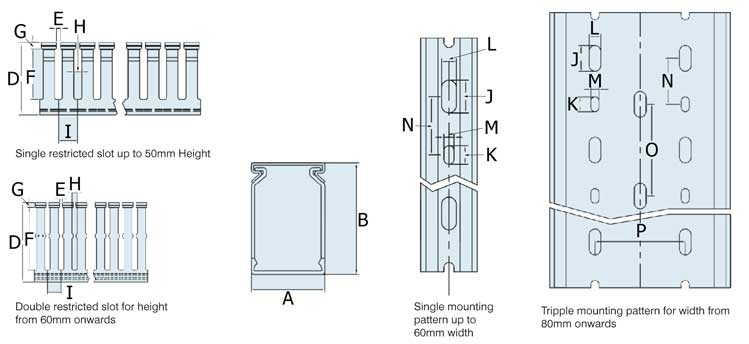

| Nominal Duct Size (mm) |

Dimensions (mm) |

| A |

B |

T* |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

P |

| 25 |

25 |

1.6 |

22.2 |

2 |

10.8 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 25 |

40 |

1.6 |

37.2 |

2 |

25.80 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 25 |

45 |

1.6 |

42.2 |

2 |

30.80 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 25 |

60 |

1.9 |

57.5 |

2 |

45.55 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 25 |

80 |

2.2 |

77.8 |

2 |

54.90 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 25 |

100 |

2.1 |

97.8 |

2 |

83.60 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 30 |

80 |

2.2 |

77.8 |

2 |

54.90 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 40 |

40 |

1.6 |

37.2 |

2 |

25.80 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 40 |

60 |

1.9 |

57.5 |

2 |

45.55 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 40 |

80 |

2.2 |

77.8 |

2 |

54.90 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 40 |

100 |

2.4 |

97.8 |

2 |

83.60 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 45 |

45 |

1.6 |

42.2 |

2 |

30.80 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 60 |

40 |

1.6 |

37.2 |

2 |

25.80 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 60 |

60 |

1.9 |

57.2 |

2 |

45.55 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 60 |

80 |

2.2 |

77.8 |

2 |

54.90 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 60 |

100 |

2.4 |

97.8 |

2 |

83.60 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

- |

- |

| 80 |

40 |

1.6 |

37.2 |

2 |

25.80 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

50 |

50 |

| 80 |

60 |

1.9 |

57.5 |

2 |

45.55 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

50 |

50 |

| 80 |

80 |

2.3 |

77.8 |

2 |

54.90 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

50 |

50 |

| 80 |

100 |

2.5 |

97.8 |

2 |

83.60 |

3.50 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

50 |

50 |

| 100 |

60 |

1.9 |

57.5 |

2 |

45.55 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

50 |

50 |

| 100 |

100 |

2.5 |

97.8 |

2 |

83.60 |

3.40 |

4 |

10 |

14 |

8 |

6.5 |

4.5 |

25 |

50 |

50 |

*T - thickness

Formula for Calculating fill Capacity

Number of Wires= |

| Duct W x H |

| 1.75 x (Wire O.D.)²/2 |

|

Typical raw material properties of Wiring Duct

| Property |

Units |

ASTM Test |

PVC |

| Specific Gravity |

|

D792 |

1.43 |

| IZOD Impact Strength |

Kg.cm/cm |

D256 |

7.5 |

| Flexural Strength |

Psi |

D790 |

10 900 |

| Flexural Module |

Psi |

D790 |

382 000 |

| Tensile Strength |

Psi |

D638 |

5 500 |

| Compressive Strength |

Psi |

D695 |

8 600 |

| Water Absorption |

24Hrs-% |

D570 |

0.1 |

| Hardness |

Shore D |

D785 |

78D |

| Dielectric Strength 50Hz, 25°C,s/t |

Kv/mm |

D149 |

36 |

| Volume Resistivity |

Ohm-cm |

D257 |

6.1x10 |

| Heat Deflecting F @ 264 psi |

F |

D648 |

Up to 158 (70°C) |

| UL 94 - Flammability |

|

|

V0 RoHS |

|

|

File description

|

File type

|

Download link

|

|

Wiring Ducts catalogue

|

PDF

|

Download link

|

|

|

|